What is Laser Remelting?

Laser remelting is a non-additive process that utilizes a laser to impart energy to the surface of a base component. This changes the part’s microstructure to achieve new hardness or performance goals. Kondex technology prevents surface vaporization, which could otherwise have unintended performance results. With more than a decade of success with this operation, Kondex holds the expertise needed to achieve your product strengthening goals.

DuctileArmor™ Protection

In addition to laser remelting of steel products, Kondex is seeing significant success in laser remelting austempered ductile iron. The resulting improved microstructure acts as armor against wear and material fatigue.

Case Study: DuctileArmor™

Austempered Ductile Iron (ADI) is a common material for many equipment components in a variety of industries. Although ADI offers higher toughness and better wear characteristics over traditional ductile iron (DI), methods of further enhancing these properties are highly sought after. Kondex has done just that.

We have developed a process that can drastically increase the wear resistance of DI & ADI locally, using our state-of-the-art laser technology. Our laser enhanced technology is opening doors to new high-wear opportunities and changing the way engineers look at designing new products.

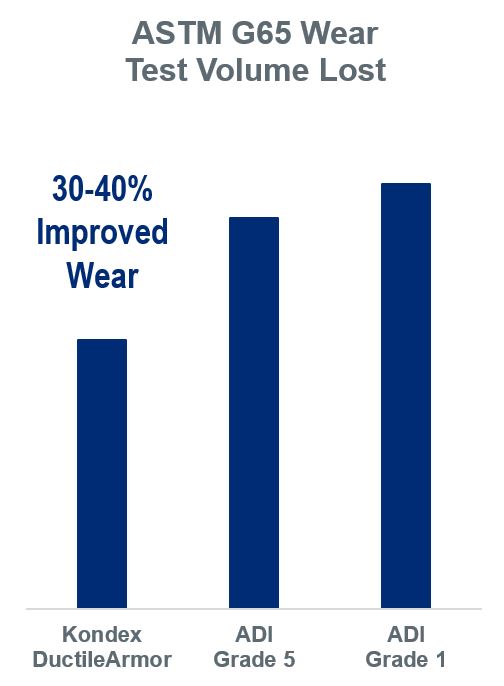

We have been testing laser enhancements on a number of both DI and ADI components and have been very pleased with the results. As shown on the chart, lab tests are revealing a 30-40% improvement to wear life on the Kondex enhanced ADI over traditional ADI components.

In addition, by applying laser enhancements to lower grade ADI components, we achieved a surface hardness value equal to or better than that of higher-grade ADI parts — without sacrificing the toughness. This essentially allows for greater cost and material flexibility in your designs, while addressing the balancing act between ductility and wear when selecting component material grades.

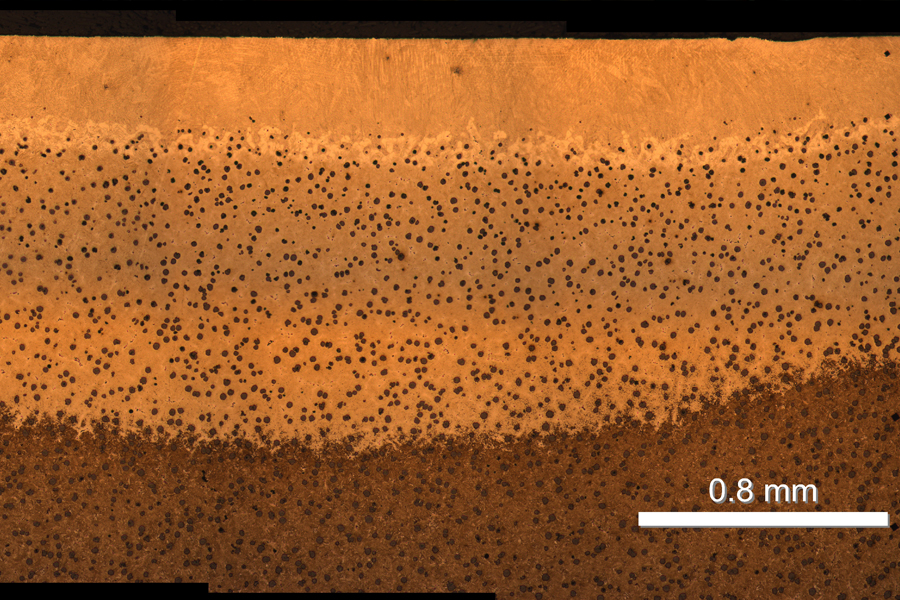

Micrograph analysis of laser enhanced ADI reveals over 50% improvement in hardness of this base part.

Project Review

Contact us to review your product goals and determine if laser remelting is a solution.